Engineering failure investigations and corrosion

The core of UQMP's business lies in failure analysis - the systematic investigation of the mechanisms and causes of equipment failure and damage. UQMP has a full investigative facility including the resources of a full scientific laboratory. The team provides independent scientific and engineering investigations and expert opinion in relation to the causes of failure of materials, components and structures. Experience includes failures occurring by fracture and fatigue, wear, corrosion and mixed modes, leading to death, injury or interruption to business operations. Investigations performed by a combination of metallurgical (notably microscopic) and mechanical (quantitative) methodologies.

Our methodology for conducting a rigorous failure analysis for metallic and nonmetallic materials may include1:

- information gathering

- preliminary, visual examination

- nondestructive testing

- characterization of material properties through mechanical, chemical and thermal testing

- selection, preservation and cleaning of fracture surfaces

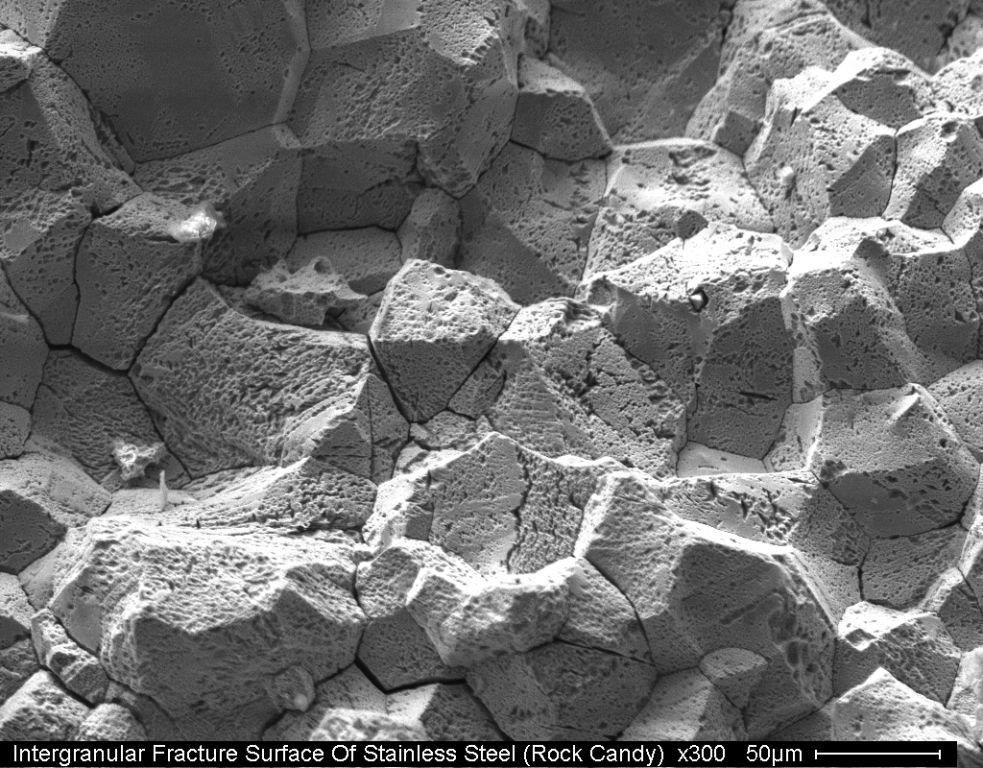

- macroscopic examination of fracture surfaces, secondary cracking and surface condition

- microscopic examination

- selection, preparation and examination of cross sections

- identification of candidate failure mechanisms

- stress/fracture mechanics analysis

- testing to simulate failure

- data review, formulation of conclusions

- formal reporting and collaborative peer-review.

1. Adapted from Moalli, J., Fractography of ABS, in Plastics Failure - Analysis and Prevention. William Andrew Publishing